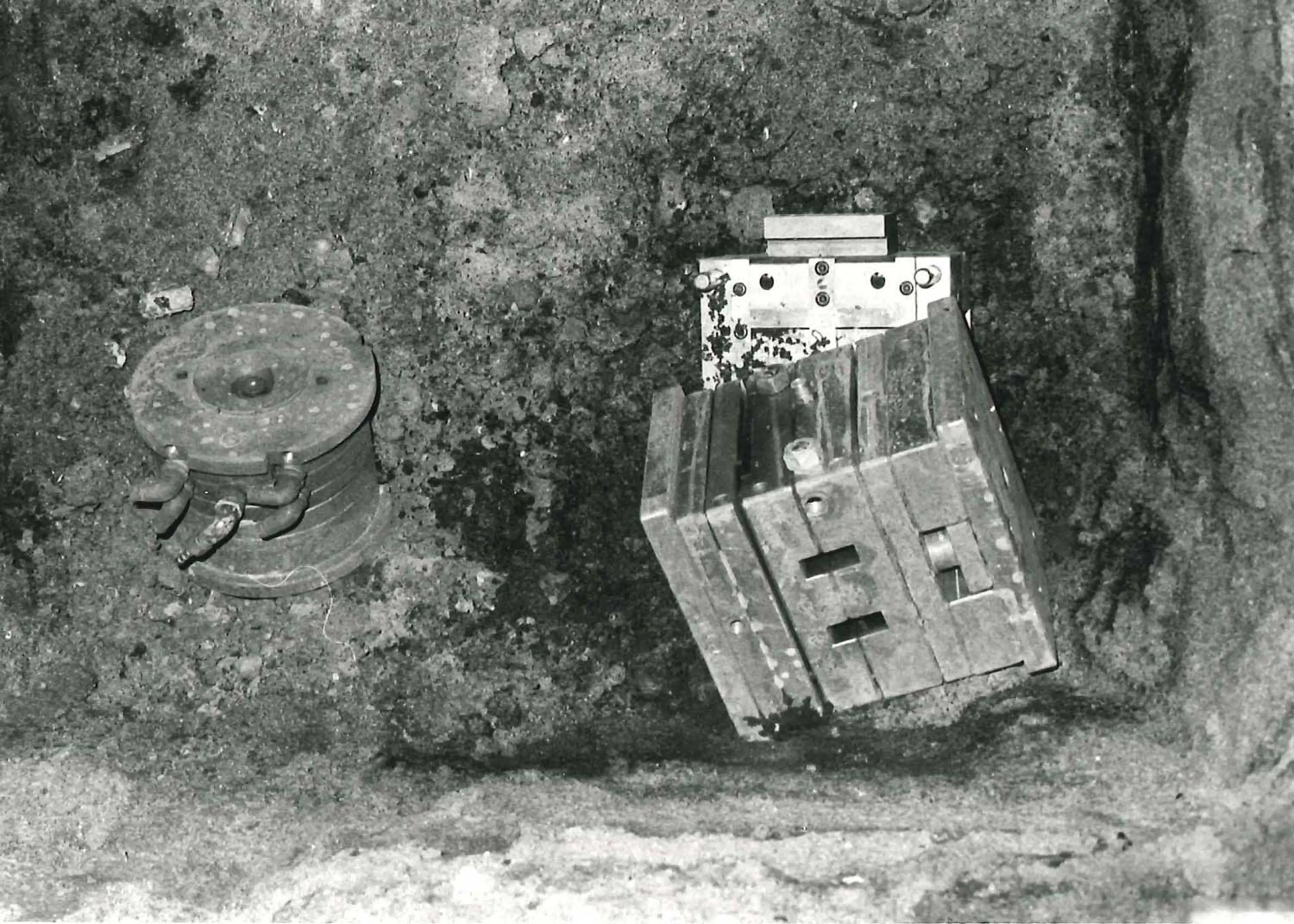

Until about 1980 moulds no longer used in production are disposed of by casting them in the foundations of LEGO buildings erected at the time. In 2016 during demolishing of the old LEGO Headquarter, 120 old moulds were discovered under the buildings. The oldest mould dated to the early 1950s and the newest to early 1970s.

Some of the moulds from the foundations of the former LEGO Headquarters

After the company stops casting its old forms in the foundations, it switches instead to having them melted down by Frederiksværk Stålvalseværk, a Danish steel rolling mill. Destruction of obsolete moulds is subject to absolute security – for example, the driver who has delivered the moulds to the rolling mill, must personally witness that the moulds are destroyed. This practice continues until 2002, when Frederiksværk Stålvalseværk goes bankrupt and ceases to operate.

From 2002 to around 2019 all obsolete moulds are sent to the LEGO factory at Kornmarken, Billund, where disposal of all moulds is administrered. This also applies to moulds from moulding factories in Mexico, Czech Republic, and Hungary. The disposal company has been certified by LEGO Juris A/S to dispose of the moulds. Moulds are shipped to the port of Aalborg in northern Jutland, where a “burner” cuts a hole through the mould, melting the cavities and rendering the mould useless. The process is not monitored on every occasion, but random checks are made to verify destruction. In addition, the LEGO Group has moulds disposed of in China. In this case it is moulds which are the property of the LEGO Group, but which have been manufactured by a supplier and used by an external partner. In China all mould disposal is monitored.

Today mould destruction is carried out on each manufacturing site, but selection for moulds to be destroyed is still coordinated from Billund.

Sustainability in mould destruction

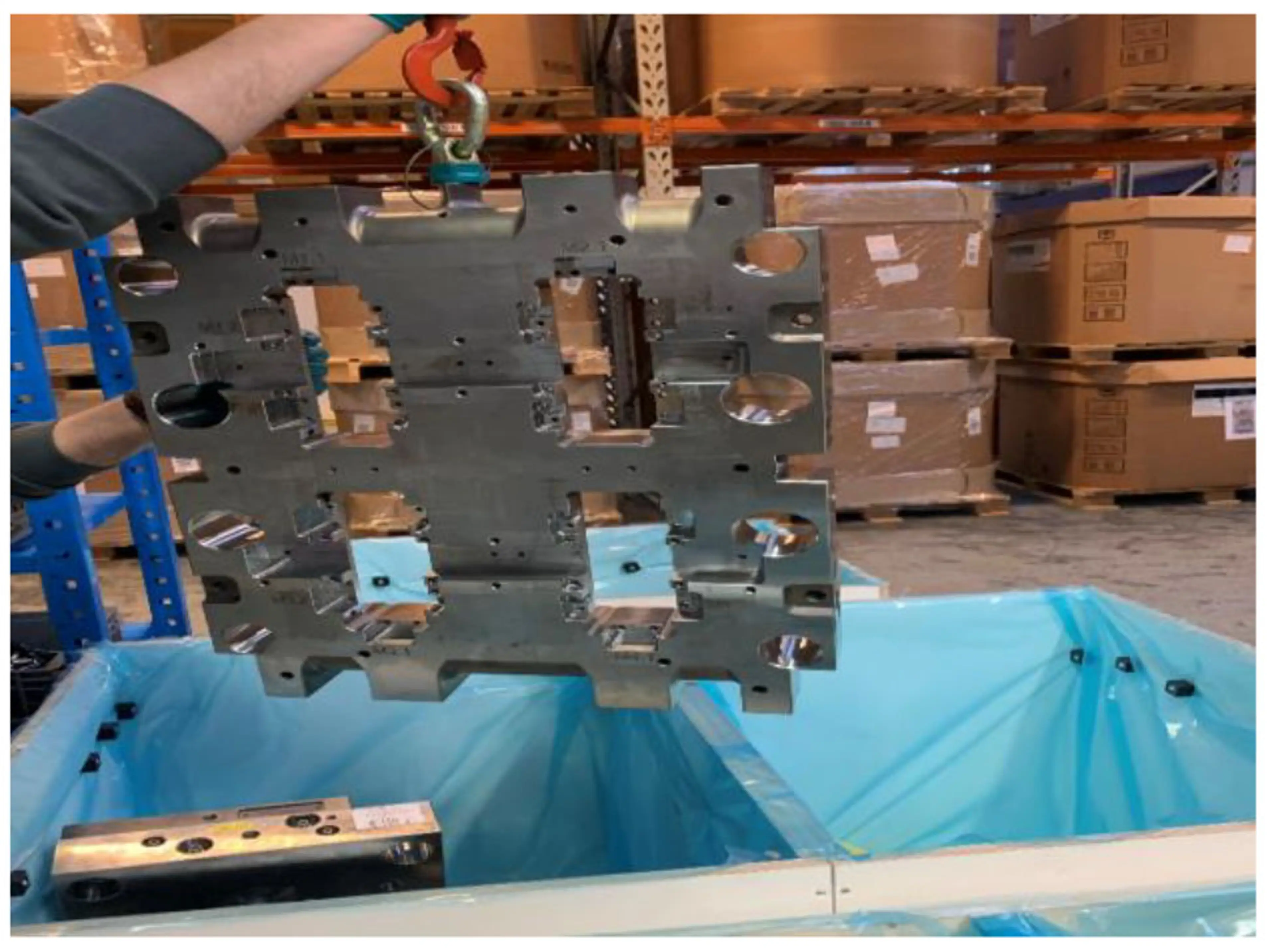

Sustainability is playing a big part in the whole LEGO Group and therefore also in mould destruction. In Billund a team is working on best practice in handling moulds in order to secure the reusable parts. The selected moulds are carefully disassembled prior to destruction and reusable parts are removed and sorted, before being returned to the Mould Maintenance Department. At present this recycling-process takes place in Billund, but hopefully the process can be extended to the other LEGO manufacturing sites.

Sorting of mould parts