The LEGO Group go through a lot of changes during the 1970s including the introduction of an even stronger focus on product safety, creating a completely new organization in the US and setting up a new production facility outside Denmark. All is a part of navigating an ever-changing business landscape.

Modernizing production

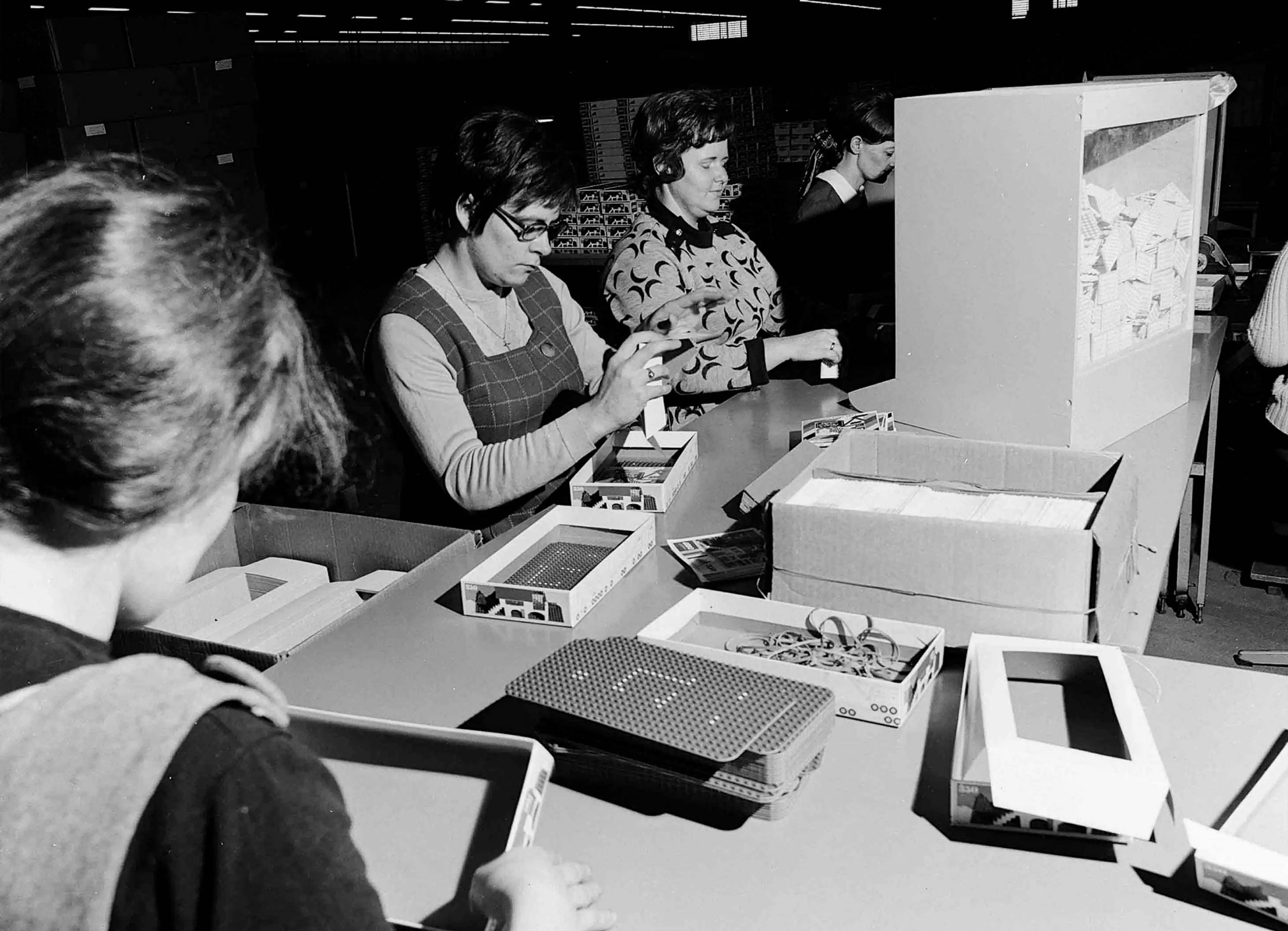

Production faces urgent challenges with increasing demands for product complexity, higher productivity and quality improvements in the light of new environmental and safety standards. When the company introduces “mass production”, it opts for a high degree of automation in the manufacturing process.

The factory at Højmarksvej, Billund 1973

Taking safety seriously

Increasing environmental awareness among the population and in pollution debates in the media bring the LEGO product to public notice in the early 1970s on account of its content of the cadmium pigment in the yellow and red bricks. It is the first time a problem of this nature has touched the LEGO Group, which acknowledges a need for more knowledge in the area. The matter launches a development, which to an even higher extent highlights product safety. The company realizes that it has to act to raise the level of product safety. In 1974, the LEGO Group joins a standardization group whose task it is to work actively for a European standard for toy safety. This activity broadens in 1975 with the company’s membership of the EEC commission in Brussels charged with drafting an EU directive on toy safety.

New logo

In 1973, the LEGO logo undergoes a graphic facelift. The square from the previous (1964) logo is retained but in order to focus upon the company's name, designers remove the word “system” and the five colored stripes. The softly rounded lettering is tightened up, and a double contour is introduced – black/yellow – around the white letters, very typical of the 1970s.

The LEGO logo as it appeared from 1973 to 1998

Foreign activities

After some disagreement with the LEGO Group's partner in North America, Samsonite Corporation, well known for its production of luggage products, the LEGO Group negotiates a deal in 1972 to buy back Samsonite's licensed rights for the production and sale of LEGO bricks in the US. The agreement comes into force on January 1, 1973. The LEGO Group now assumes responsibility for the production and sale of LEGO bricks in the United States and later in 1973 builds a LEGO factory in Brookfield, Conn., at the same time setting up a sales organization. LEGO USA (LEGO Systems Inc.) is a reality. In 1975, the company moves its organization and production to Enfield, Conn. From a position far behind the European market, the American market makes steady forward progress after the purchase of production and sales rights for the USA. Today, the US is the LEGO Group's largest market in terms of sales.

Building site in Enfield 1975, from left: Jack Sullivan (LEGO Systems Inc.), Godtfred Kirk Christiansen, governor Ella Grasso, Vagn Holck Andersen (LEGO A/S) and Kjeld Kirk Kristiansen

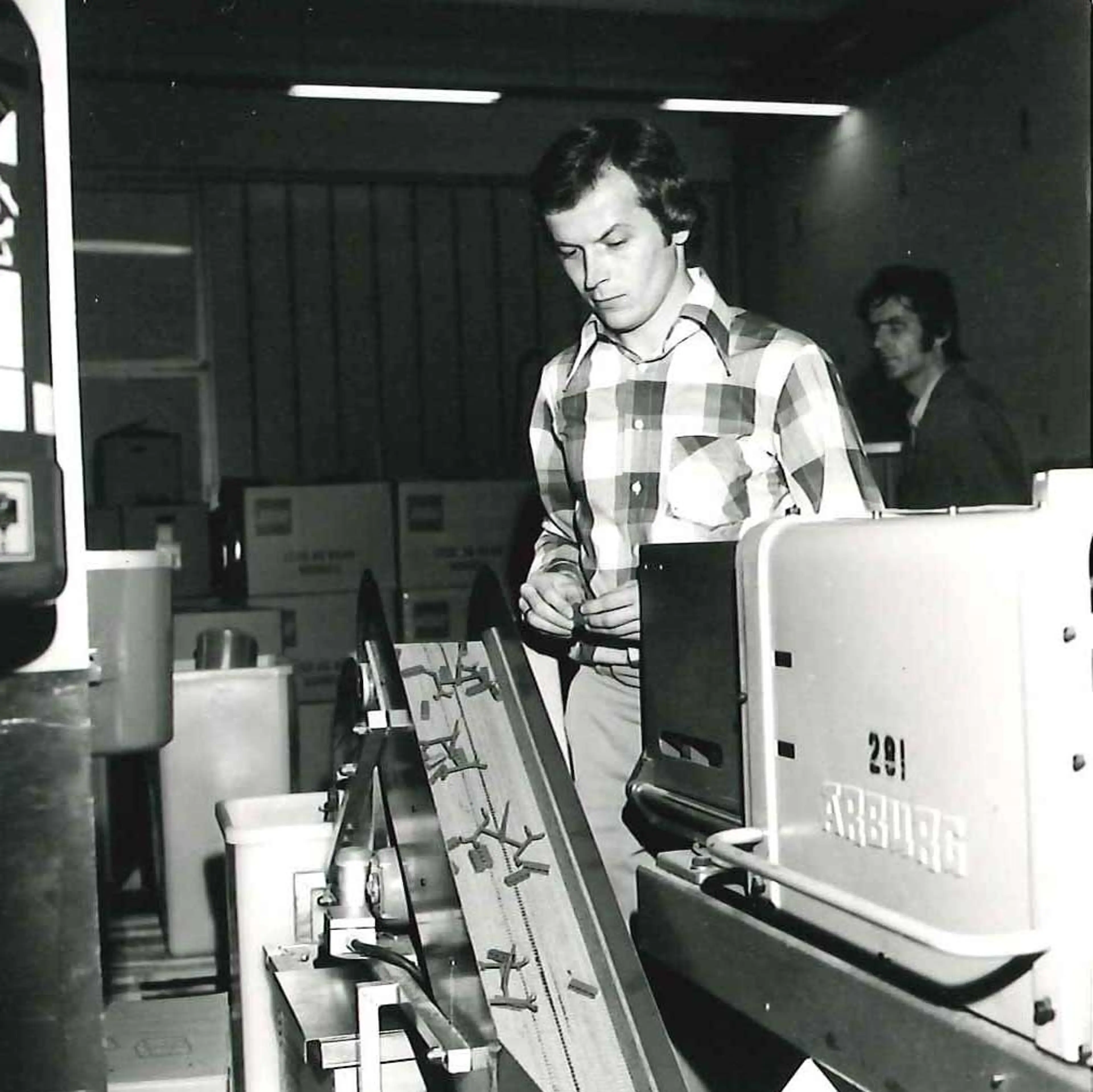

In 1974, a test molding shop for process and tooling development is set up in Baar, Switzerland. Hans Schiess, who for many years was technical director of the production in Billund head up the new facility. This become the first LEGO molding shop outside Denmark.

Third generation LEGO owner Kjeld Kirk Kristiansen at a production line in Switzerland