Quality is and has always been one of the LEGO Group's values. It permeates everything we do and shines through in the company motto: Only the best is good enough. Here is a small account of how this focus translated into improvements of the production methods etc. in the early era of plastic molding.

Own molding tools and new technology

The LEGO Group has been manufacturing product molds in Billund since 1953. However, with sales increasing rapidly, production in Billund is under pressure, and the need for added capacity is more than Mold Production can deliver.

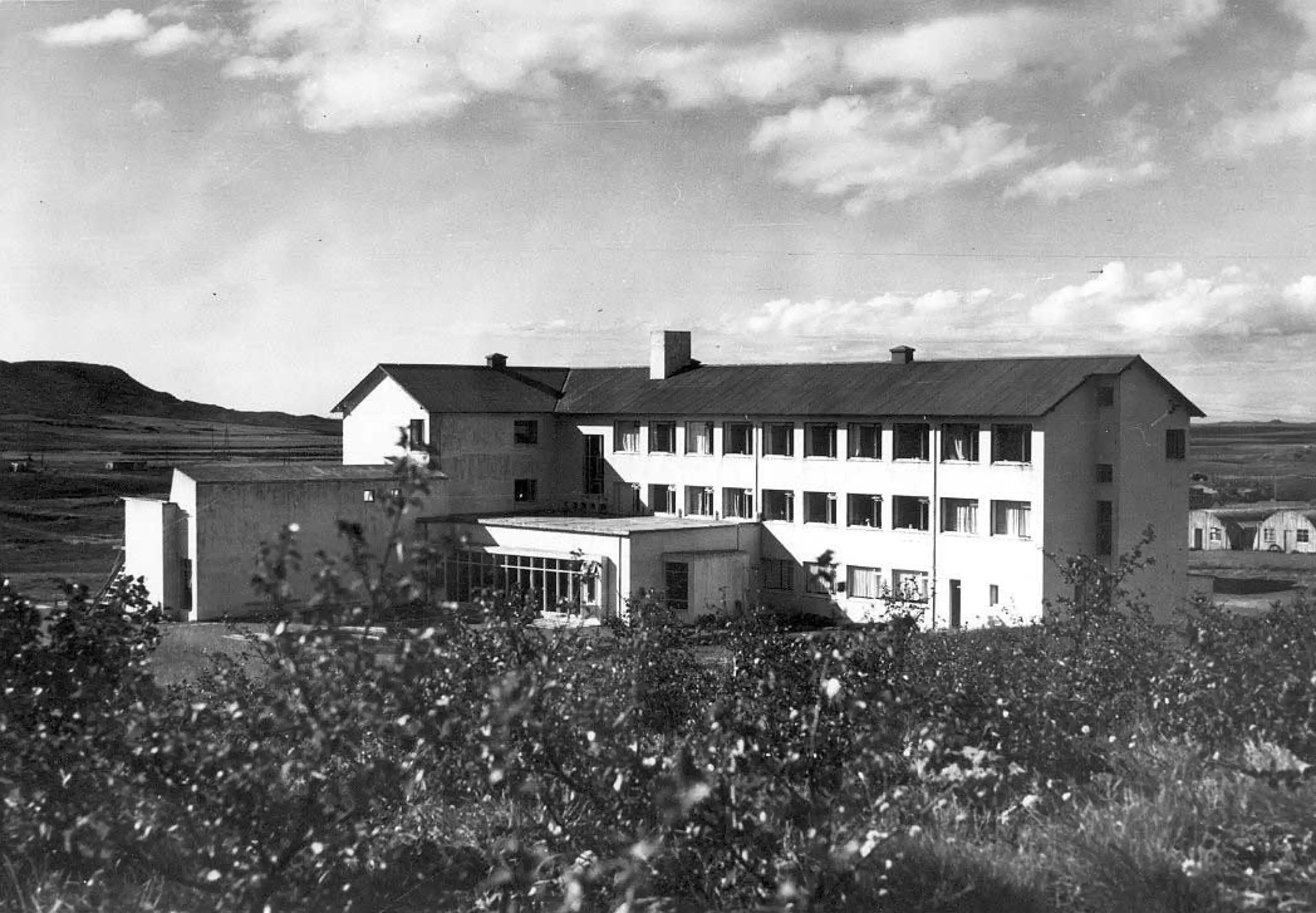

There are few toolmakers to be found in Billund, and in 1959, the company opens LEGO Form in Vejle about 30 km away. This unit, together with a tooling department set up the previous year in Hohenwestedt, Germany, supplies the necessary extra precision-made molds.

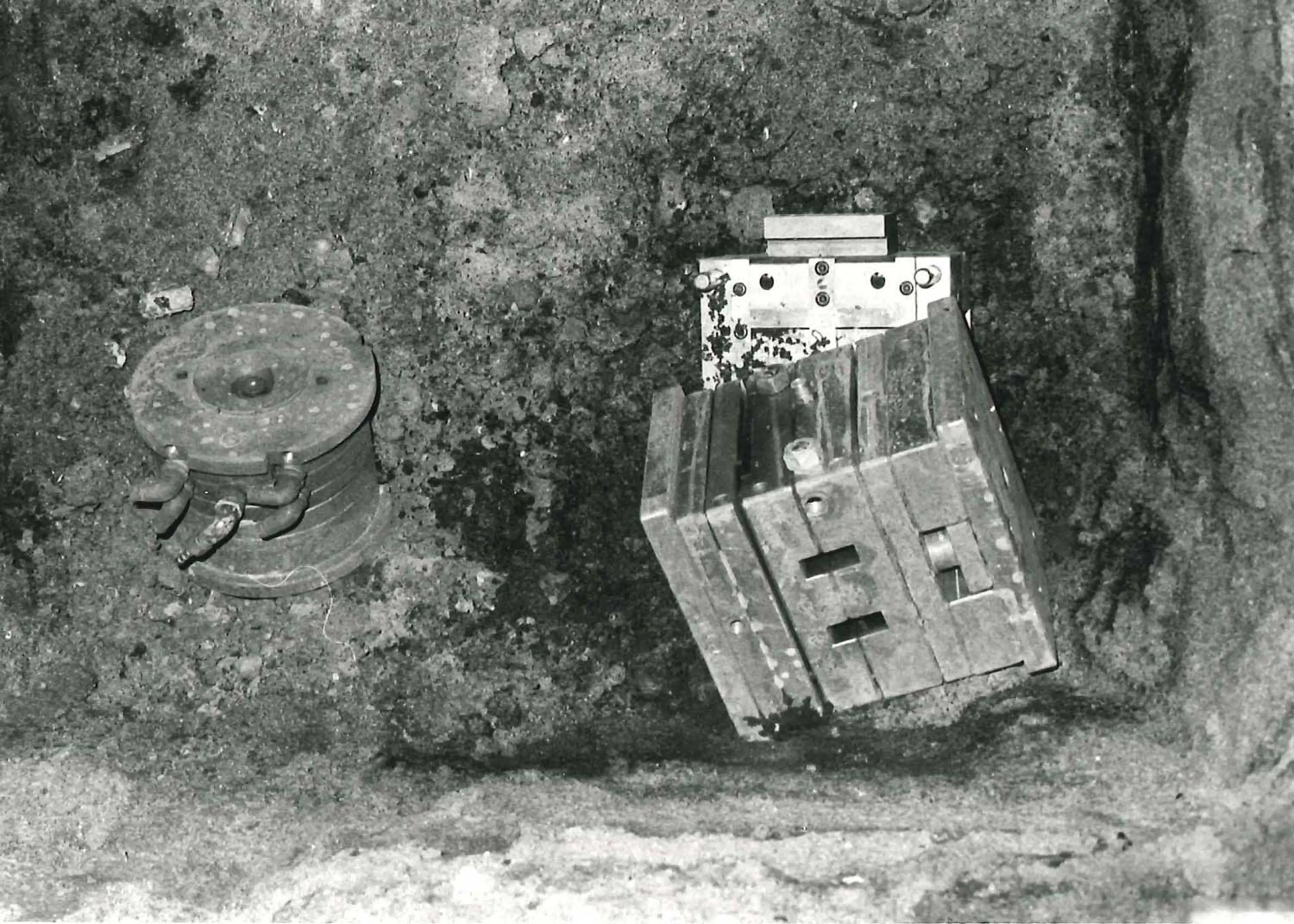

Mold production in Billund, 1957

The entrance at LEGO Form in Vejle, 1974

Ramping up the organization

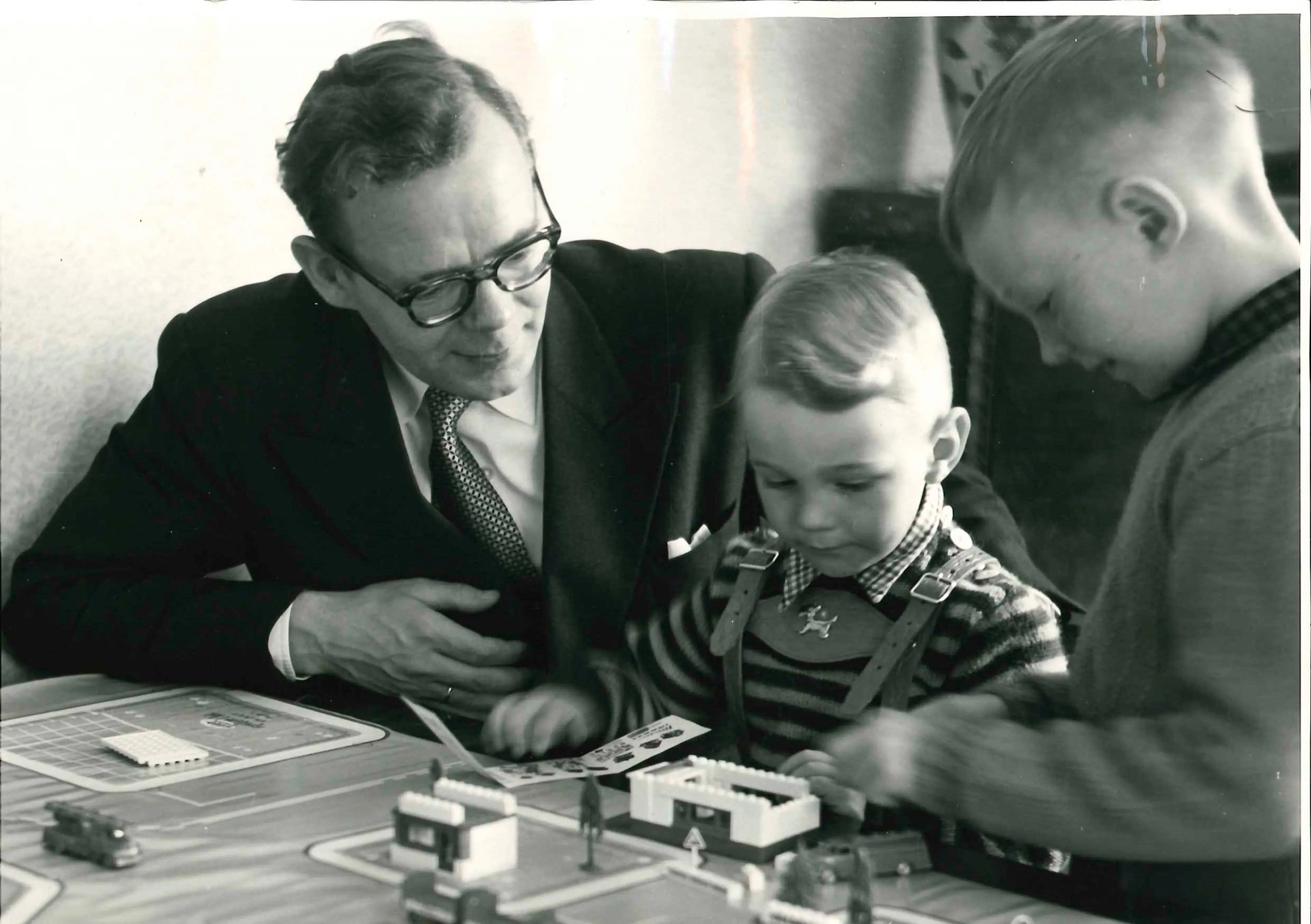

In the search for new skills for the organization, the company takes on a number of experts to head up various areas such as marketing, manufacturing and legal issues. In 1961, Godtfred Kirk Christiansen employs Hans Schiess, a Swiss plastics expert, and the technical staff begins to grow. The appointment of Hans Schiess is important to the development of raw materials, molds, injection molding machines and the actual molding process.

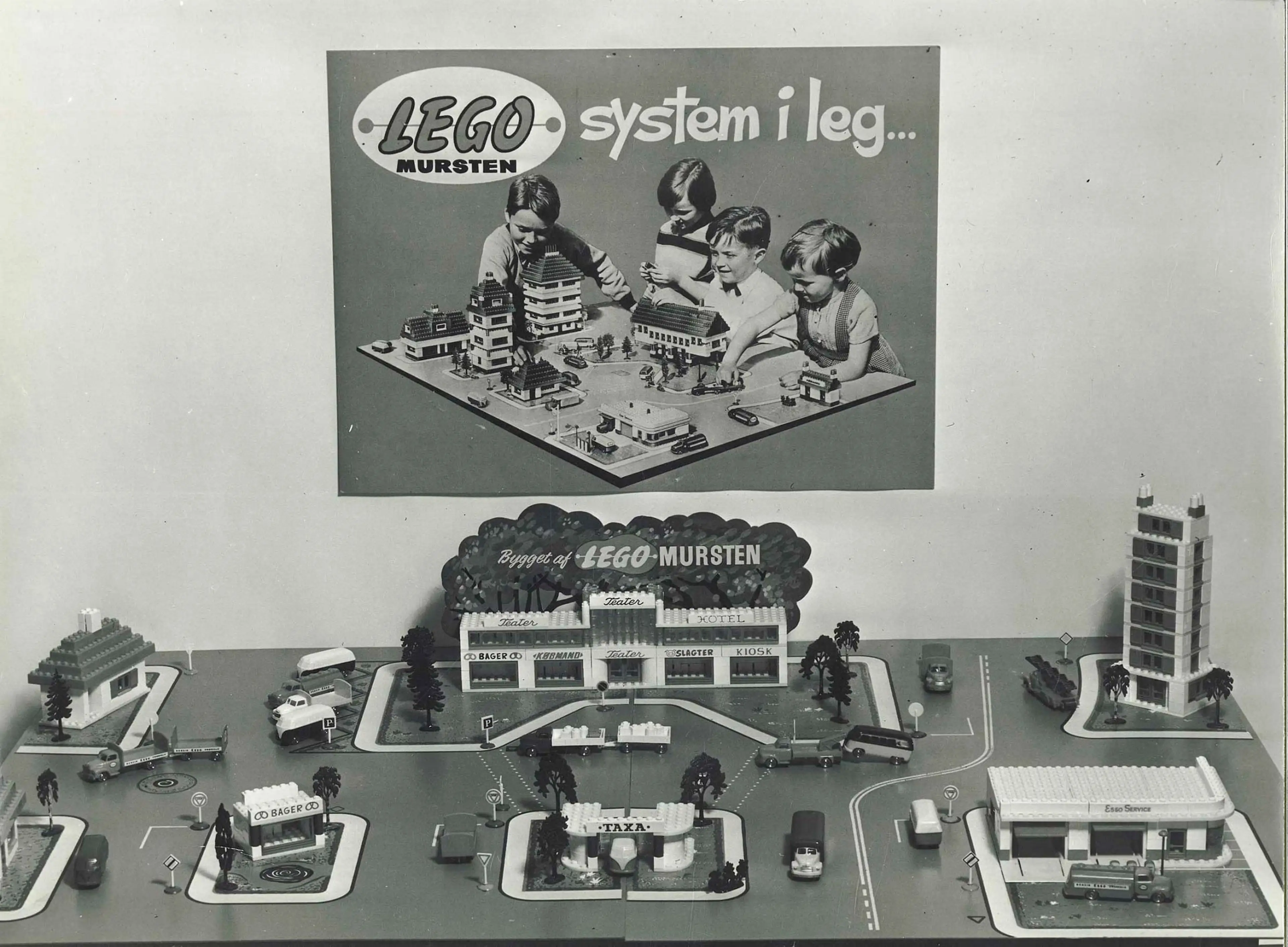

Following the crucial decision to concentrate all efforts on the LEGO System in Play in 1960, Godtfred Kirk Christiansen lays down a company rule that “No one must be able to do this better than us”. In addition, he outlines developments so far: “We know our idea is a good one. We want only the best ... we must make better bricks from even better material on even better machinery. We must get the best people that money can buy for our company.”

From Cellulose Acetate to ABS

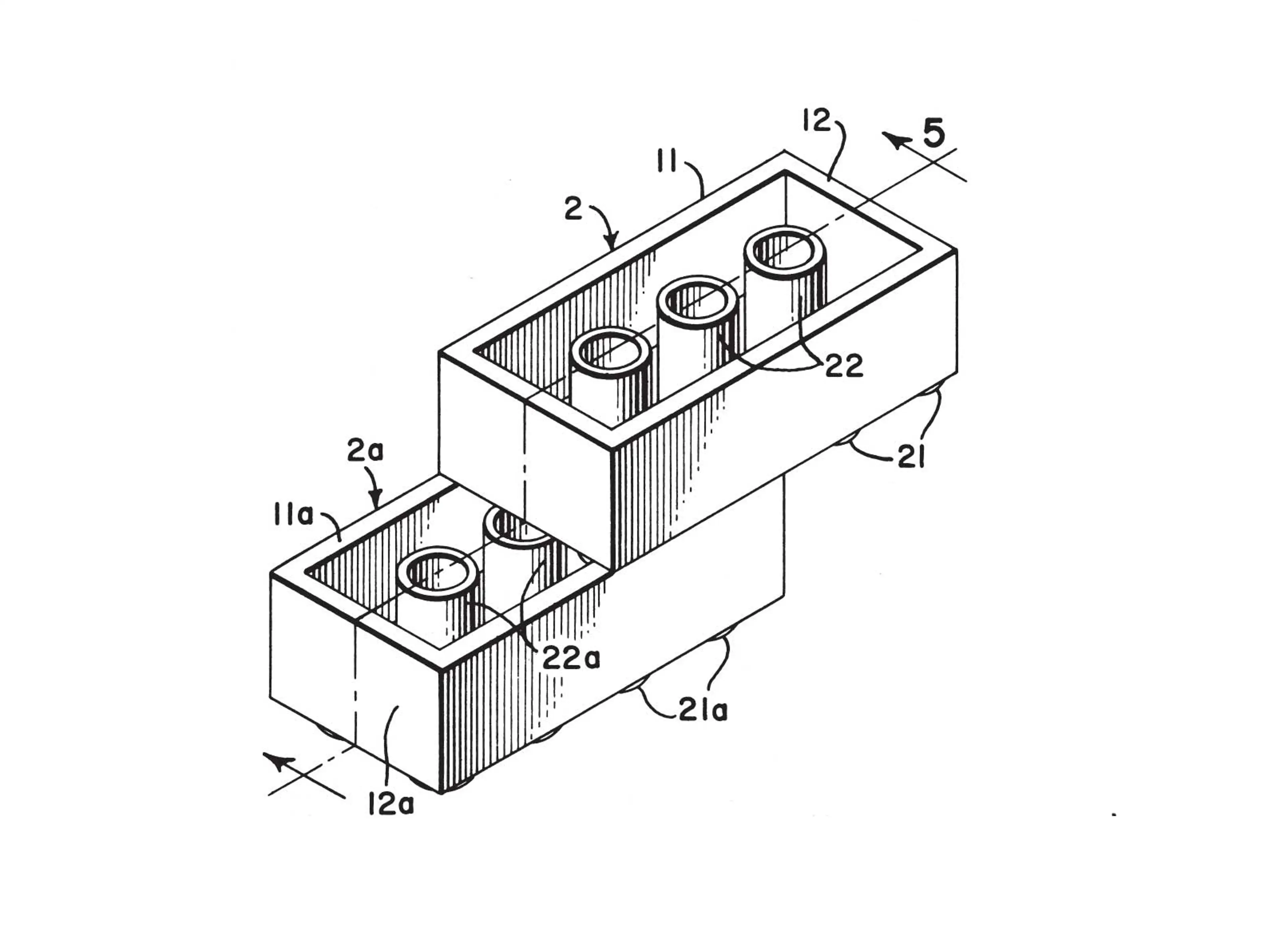

After a series of tests the raw material used until now (cellulose acetate, which is based on wood) is discontinued in 1963 in favor of the more stable and color fast ABS (acrylonitrile butadiene styrene). Material improvements permit a greater precision in molding, which is now done to an accuracy of 1/200 mm. Principles are approved for the conscious control of the molding process and become the LEGO molding philosophy, defined by the company’s plastic expert, Hans Schiess.

The LEGO Molding philosophy can be explained like this: All the experiments and calculations that Hans Schiess makes, enable us to gather knowledge of injection molding and the quality of molded items. At the same time the molded pieces can be optimized, remaining within the range of desired quality, but also with a shorter molding cycle. All this combines to develop and improve the company’s molding machines.

Hans Schiess, 1963

Quality control

Greater efficiency and automation speed up the manufacturing process but also increase the risk of error. Quality however, will not be compromised. A quality control department with a staff of 13 is set up in 1963. Quality has always been one of the company’s key values – right from the day Ole Kirk Kristiansen set up the business in 1932.