In the late 1970s, the LEGO Group adopts a new packing method: the pre‑pack plastic bag. The increased pace of production and packing of LEGO products means that too many sets arrive in the consumer’s hands containing the wrong number of LEGO bricks.

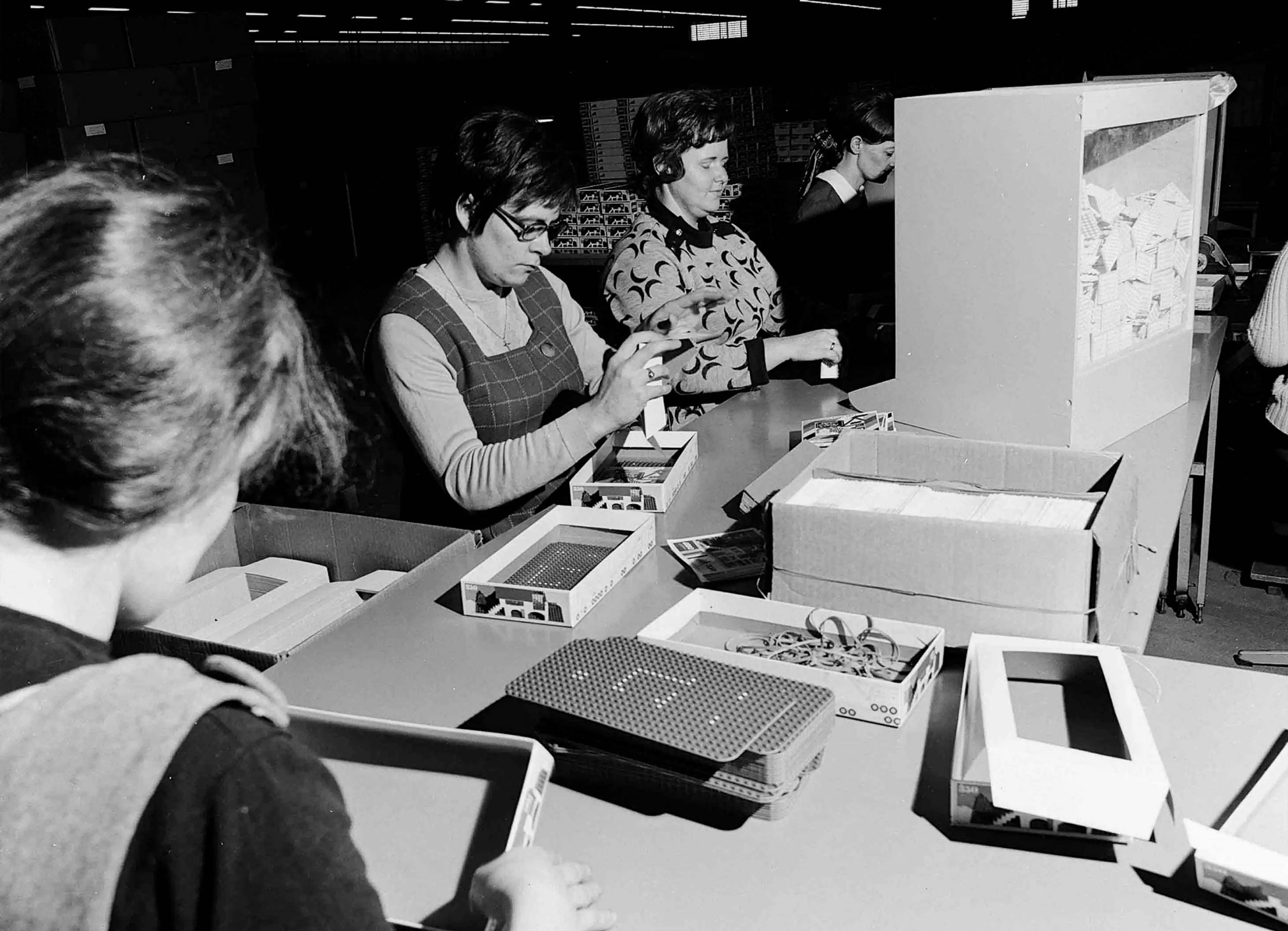

Studies reveal that nearly half the sets may contain too few or too many elements. This is to some extent because much of the work of filling sets is done manually, and all elements – large and small – are mixed loose in the box. As many as 20 or more operators sit along the conveyor belt, next to the counting machines. It is a complex process – with a risk of error.

Packing facility, 1960

Packing line, 1961

Even though care is taken in selecting the correct elements, it is impossible to check that the final contents of the set are correct when all the bricks and pieces – big and small – are jumbled together, and the weighing machine cannot show whether the box contains the right number of tiny parts.

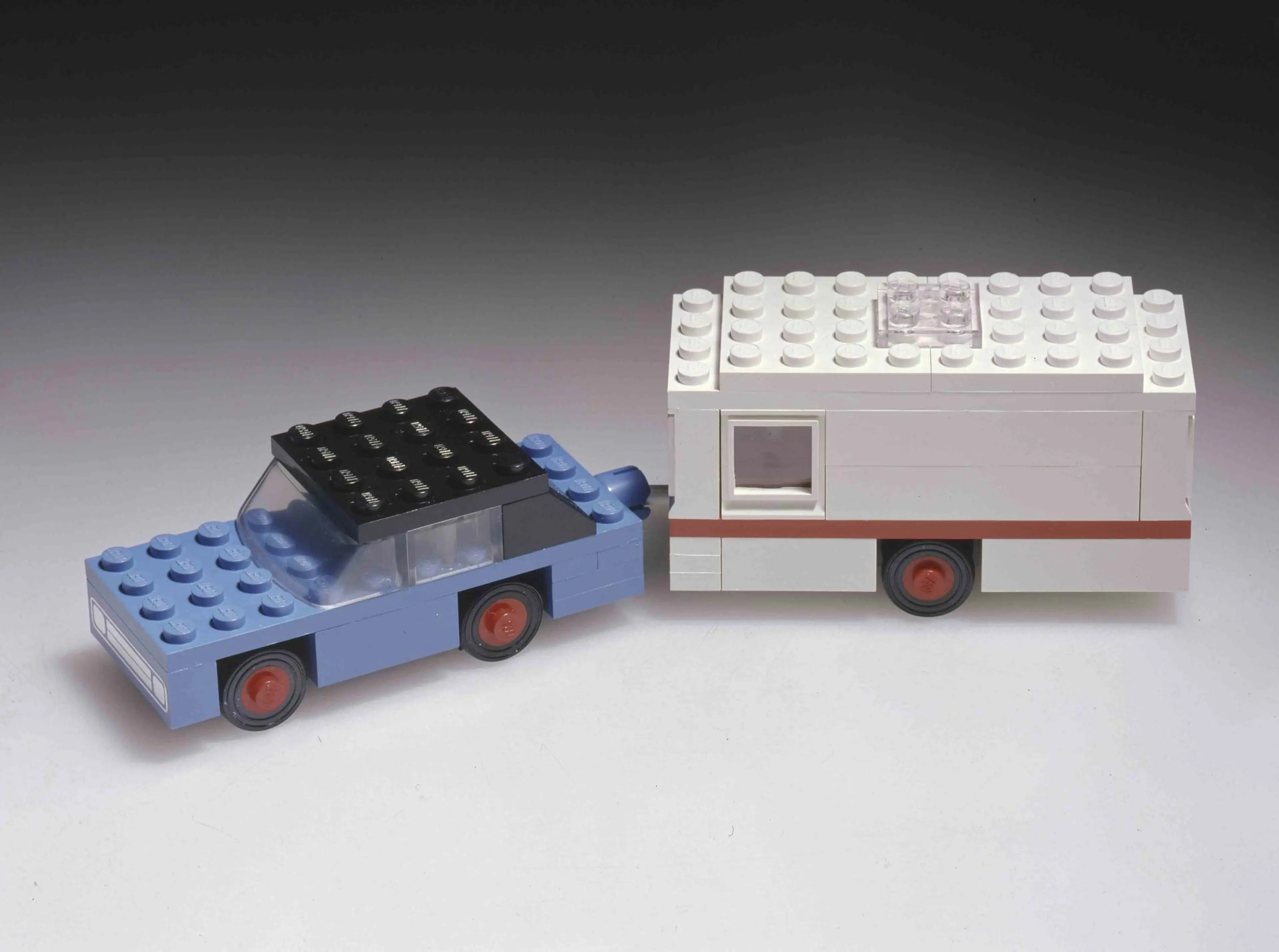

The problem is solved by introducing the pre‑pack concept: separating the large and small elements from each other by pre‑packing them in separate plastic bags. The bags are then placed in the LEGO sets in the Final Pack department, the area in which the individual bags of LEGO bricks are packed in LEGO sets.

Early pre-pack line, 1980

.jpg?width=3840&quality=68&auto=webp&format=webply)

A counting machine at work, 1980

In the early 1980s the pre‑pack lines are upgraded. Counting machines, each fitted with photocells, are given a “capacity control” feature meaning that they are able to check that the correct number of parts have been transferred from the counter into the little tray on the conveyor. Thanks to this function, the counter can “judge” whether each element is of the right size – and can remove elements of the wrong size.

The introduction of pre‑pack bags dramatically cuts the number of sets containing the wrong number of parts. In 2008 – 30 years after adoption of the system – faults average out at only three per million possibilities.